Are you figuring out whether you need wire mesh or rebar to construct your concrete patio or driveway?

If so, you must look at the factors and properties of these products since both offer significant strengthening and long-lasting advantages.

So let’s examine how these two processes increase the sturdiness of a complex product like concrete.

Tracking down the best material for a concrete patio or driveway can be confusing.

Both rebar and wire mesh can work well depending on the size and shape of your patio or driveway. One may offer you more to consider as opposed to another.

Although both have pros and cons, there are noticeable distinctions between each that prove they serve different purposes.

There are crucial guidelines that your contractor must adhere to while installing a concrete driveway to ensure it looks nice for many years.

The craftsmanship and materials used to build your driveway significantly impact how it looks and functions over time.

Therefore, grasp the following information before constructing a flawless and functional driveway.

This article will discuss the appropriate applications, types, sizes, and installation techniques of rebar and wire mesh. We aim to give you the knowledge to decide whether your project calls for concrete reinforcing mesh or rebar.

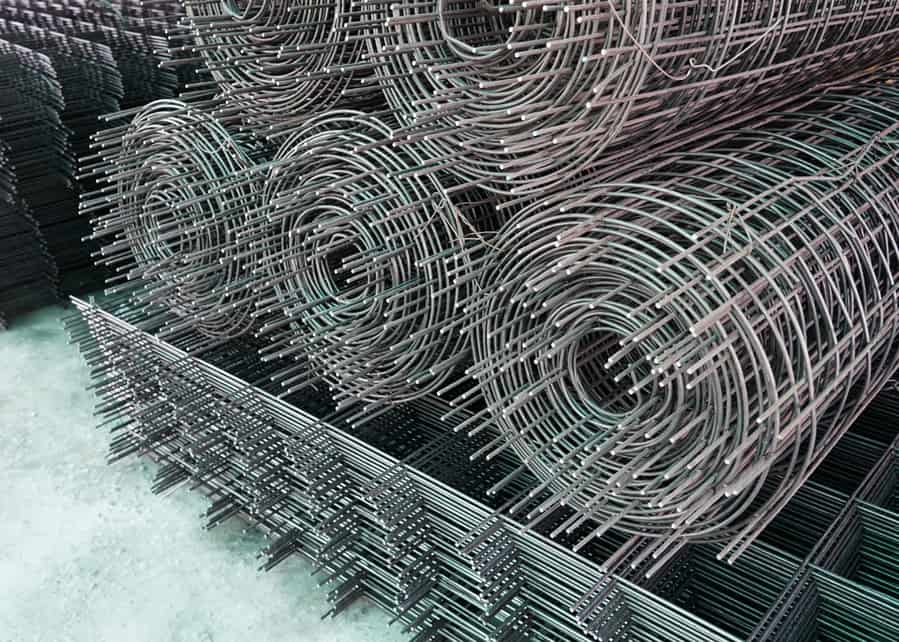

Wire Mesh: What Is It?

Wire mesh is the coolest form of weakened, deformed steel.

The use of wire mesh gives the concrete more durability and hardness. It is essential for providing the necessary support when the concrete sets.

Moreover, it also aids in preventing gaps and cracks.

Mesh reinforcement encourages the preservation of the concrete’s uprightness against fracture throughout its life.

Rebar: What Is It?

Rebar, also known as reinforcing bar, is made from steel-like wire mesh.

These spherical bars have seams and are typically available in thicknesses that vary by 1/8th inch.

Rebar takes up more room than wire mesh since it is set in more significant square portions.

Regarding providing depth and supporting the structural design, rebar is crucial as it also avoids cracks.

Wire Mesh vs. Rebar – Factors To Consider

Now that you know the main distinctions between the two, you may need clarification on which to select.

So, if this topic keeps crossing your mind, here are a few things to think about before choosing between the two:

1. Price

Rebars are more expensive than wire mesh. They are manufactured with thin steel bars and are available in rolls.

They can cost you more labor as their price varies depending on the width of the bars.

2. Support

Rebar is unquestionably more potent than wire mesh when considering the support constraint.

Rebar is a material that many builders believe is for commercial projects.

It is always an excellent alternative for thicker driveways and places that entail more traffic.

3. Strength

Both rebar and wire mesh cannot work alone to prevent cracking. When fractures develop in the concrete, they can work well together to hold it in place.

Based on the contraction and expansion qualities experienced at various temperatures, the steel-reinforcing mesh behaves effectively.

So, you must lay it out carefully to perform its purpose and function better.

4. Placement Time

It is essential to consider how the placement time would impact your project’s timetable.

You must install the rebar in concrete more slowly than the mesh.

So install bars independently and tie each intersection to secure them (or, at times, even weld). In the meantime, you must trim the wire mesh to fit the slab size while unrolling (if using rolls) or inserting (if using sheets).

Wire mesh would be the best choice if you have a tight deadline or would like to save money on labor.

Rebar and Wire Mesh Reinforcement

Your driveway will have more structural strength if you use steel reinforcement, which is crucial if the slab has to bear heavy traffic.

Although this support cannot stop fractures, it can assist in keeping them from spreading.

Therefore, wire mesh or 12-inch (#4) steel rebar are acceptable concrete reinforcement forms.

You can use wire mesh for driveways 4 to 5 inches thick. But use rebars for roads that are 5 inches or thicker.

Make sure to lay the rebar in a grid pattern with a 12-inch gap between each bar.

Also, place the blocks beneath the reinforcement in all scenarios to keep the level within concrete.

Choosing the Suitable Option

To choose a suitable option, you must understand your project’s demand, whether it needs rebar, wire mesh, or both.

In residential applications, wire mesh performs well. Along with walkways and other paved surfaces, it can aid in preventing driveway cracking.

It’s also an excellent option for DIY projects because the material is simple.

Rebar, on the other hand, takes longer to install, but it provides the support required for heavy-load industrial and commercial building projects.

They also support walls, floors, and other load-bearing structures.

Summary

As you can see, we’ve compared the rebar and wire mesh properties for your better understanding.

Now you have a variety of valuable options when it comes to strengthening your brand-new concrete slabs.

Hence, remember all these options whenever your team decides whether to choose rebar or wire mesh for your upcoming concrete building job.

Frequently Asked Questions

Is Fiber Mesh Admissible for Concrete Driveways?

Fiber mesh is an excellent reinforcement material for concrete driveways.

Polymer fibers are straightforward as they reduce the need for on-site labor and resist corrosion.

Moreover, wire mesh concrete is frequently more expensive than fiber mesh concrete.

How Should I Use Wire Mesh in Concrete?

In concrete slabs, you can use wire mesh alone or with reinforcing bars.

The mesh strengthens the pad’s flexural structure, prevents cracks, and increases its durability.

Additionally, it provides tensile strength in case the ground moves or settles. Mesh creates a homogenous grid of steel to hold the concrete together.

Give it a second thought if the pad can only support lightweight items or if the ground base becomes tightly compact.

Add an inch above the rebar for places with severe loads to provide better tensile support and cracks resistance.