Aluminum oxide is among the most durable final floor coatings available. Why, do you ask? It is because it adds a scratch-resistant layer to the flooring, preventing dents and scuffs from damaging your floor.

Hardwood flooring can be expensive, but softwood isn’t as durable and elegant as hardwood.

This option is great for you if you’re on a limited budget but still want to get that elegant, glossy aesthetic from hardwood. These floorings can even last up to 25 years!

It is an absolute joy to look at these beautiful and durable floors. However, refinishing aluminum oxide floorings can be very challenging. Refinishing aluminum oxide flooring is tricky because you can face several challenges.

Before we begin, let us go over important facts you need to know about aluminum oxide flooring.

These fundamentals can help you avoid mistakes and damage while working on this project.

- Aluminum oxide is a chemical compound of aluminum and oxygen in crystal form.

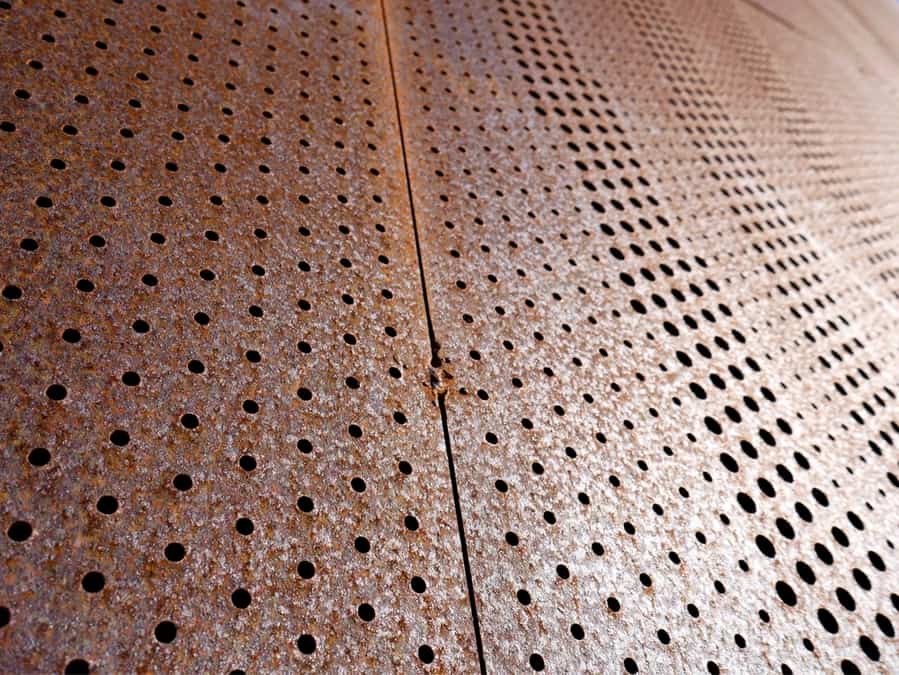

- An aluminum oxide-engineered floor has multi-layers consisting of aluminum oxide, hardwood, and other wood materials.

- Diamond abrasives must remove the aluminum oxide finish before sanding the wood. Using a regular sander right away damages the hardwood layer.

- Refinishing aluminum oxide flooring requires four phases: floor grinding with diamond abrasives, polishing with sanding discs, vacuuming, and applying an aluminum finish.

This article discusses every step of how to refinish aluminum oxide-coated floors.

How To Refinish Aluminum Oxide Flooring

Aluminum oxide is a tough crystal-like layer on top of different engineered or piled wood materials. This coating is a mineral compound of aluminum and oxygen in crystal form.

It covers a thin layer of hardwood attached to an engineered core, then another layer of wood. Unfortunately, using traditional premium sandpaper won’t work with aluminum oxide.

There are other aggressive machines available, but the problem with them is that they tend to scratch the thin hardwood layer underneath the aluminum oxide coating, ruining the hardwood layer.

Engineers have developed a way to accomplish this task without risking damage to the beautiful hardwood layer, and we will discuss each phase of this project in this article.

What You Will Need

- Floor grinding machine

- Diamond abrasives

- 60-grit sanding disc

- Vacuum

- Aluminum oxide primer

- Aluminum oxide floor finish

- Paintbrush

- Respirator and dust containment system

- Before attaching diamond abrasives to your metal bond diamond tooling system, ensure the machine is unplugged.

- Keep your hands away if the machine is plugged in to avoid accidents.

- The aluminum oxide wear layer is dangerous to your lungs. Have a dust containment system and a respirator mask.

Here are the step-by-step instructions on how to refinish aluminum oxide flooring:

Phase 1: Floor Grinding With Diamond Abrasives

- Set up your dust containment system and wear a respirator mask.

- Ensure the floor grinder is unplugged before attaching the diamond abrasives to the machine.

- Attach diamond abrasives to the floor grinder.

- Once everything is set, plug the machine, then start working on the edges of the floor.

- Work your way to the middle until all the area of the floor is done.

- Vacuum the aluminum oxide debris from the floor.

- Unplug your floor grinder, and remove the diamond abrasives.

Phase 2: Polishing the Floor With Sanders

- Load a 60-grit sanding disc into your floor grinder.

- Start sanding the edges, then work your way to the middle.

- If you’re working on a big floor, check if the disc becomes smooth after prolonged use.

- If the sanding disc is smooth, replace your sanding disc when it becomes dull.

- Remember to keep the floor grinder unplugged when replacing abrasives.

Phase 3: Vacuuming and Cleaning

- Sweep the floor to remove large debris.

- Vacuum the sawdust. Take your time on the edges to make sure everything is smooth.

- Clean the newly polished floor using a damp mop.

Phase 4: Refinishing With Aluminum Oxide

- Choose a primer that is compatible with wood and aluminum oxide finish.

- Apply an even layer of aluminum primer on the floor with a paintbrush to promote adhesion.

- Let it dry. Refer to the manufacturer’s guide on how long you should wait.

- Apply an even layer of aluminum oxide finishes with a different paintbrush on the floor.

- Please wait for it to dry, and repeat the process of applying layers of aluminum oxide.

- You may need to apply 5 to 10 aluminum oxide coatings for better results.

Why Diamond Abrasives?

Diamond abrasive technology is a modern tool made from synthetic diamond powder, resin, or metal. Diamonds are the hardest natural substance found on Earth.

Aluminum oxide floorings have metal compounds, which makes them tougher than other types of finishes.

The main idea of this technology is to grind aluminum oxide, a metal compound with a tougher material. As a result, diamond abrasives are tough and hard-wearing.

They are also used in grinding concrete, asphalt, granite, marble, ceramic, tiles, and other metal.

3 Types of Floor Grinding Machines To Use With Diamond Abrasives

- Hand-held grinding machines are compact and portable, and they can reach edges. They are great for beginners and have small floors. It is not advisable to use hand-held grinding machines on large floors because they are hard to control.

- Walk-behind floor grinders are still portable but perfect for refinishing a whole house. They give more control than hand-held grinding machines. However, they may not be able to reach corners and small edges.

- Ride-on floor grinders are the most powerful grinding machines available today. They are used in industrial projects, but they are expensive.

Summary

- Aluminum oxide is a tough wood coating made from a metal compound. To effectively remove them, you need a harder material.

- Diamonds are the toughest natural substance on Earth.

- The diamond abrasive technology is not made of the real diamond; it is made from synthetic diamond powder that duplicates the characteristic of diamonds.

- Refinishing aluminum oxide flooring requires four phases; floor grinding with diamond abrasives, polishing with sanding discs, vacuuming, and applying an aluminum finish.

- There are three types of floor grinders—hand-held grinders, walk-behind floor grinders, and ride-on grinding machines.

- It is important to wear a respirator or industrial mask when grinding or sanding floors to avoid injuries.

Frequently Asked Questions

Can You Put Polyurethane Over Aluminum Oxide?

It is possible to coat polyurethane over aluminum oxide. However, aluminum oxide is already a hard-wearing layer, so you don’t have to. Removing the old aluminum oxide layer is better if you want to refinish your floor.

How Do You Clean Aluminum Oxide Finish on Hardwood Floors?

Aluminum oxide floorings are tough to scratch, but removing them is not impossible. You will need a floor grinder and diamond abrasives to remove the aluminum oxide finish from hardwood floors.

Is Aluminum Oxide a Good Finish on Hardwood Flooring?

Yes, aluminum oxide is a great finish on hardwood floorings. They are durable, hard-wearing, and scratch-resistant.

How Do You Restore the Aluminum Finish?

To restore an aluminum oxide floor, you remove the old layer and then reapply the new coating, usually about 5 to 10 layers of aluminum oxide.