Screws are a broad category of mechanical fasteners designed with threaded shafts.

Tightening and loosening screws is as simple as twisting the screw with a screwdriver in a clockwise or anticlockwise direction.

But the screw can get stripped, a situation where the screw head wears out, making fastening the screw challenging. But what causes screws to become stripped?

There are many reasons responsible for screws becoming stripped. Some causes of screws becoming stripped can be avoided, while others can’t. The following are the leading cause of stripped screws:

- Design of the screw.

- Too much torque.

- Wrong size screwdriver.

- Rust and corrosion.

- Poor quality screw.

Understanding the factors at play in why screws become stripped helps you take proper caution to ensure you can get the screw in and out.

This article explains some of the causes of a stripped screw and how to get a stripped screw out.

5 Causes of a Stripped Screw

Having a stripped screw issue can halt whatever DIY project you are doing.

When the screw becomes stripped, it becomes challenging to tighten or loosen it, which defeats the purpose of a screw.

Knowing the cause of stripped screws in the first place is vital to avoid it.

Below we elaborate on five major causes of a stripped screw:

1. Design of Screw

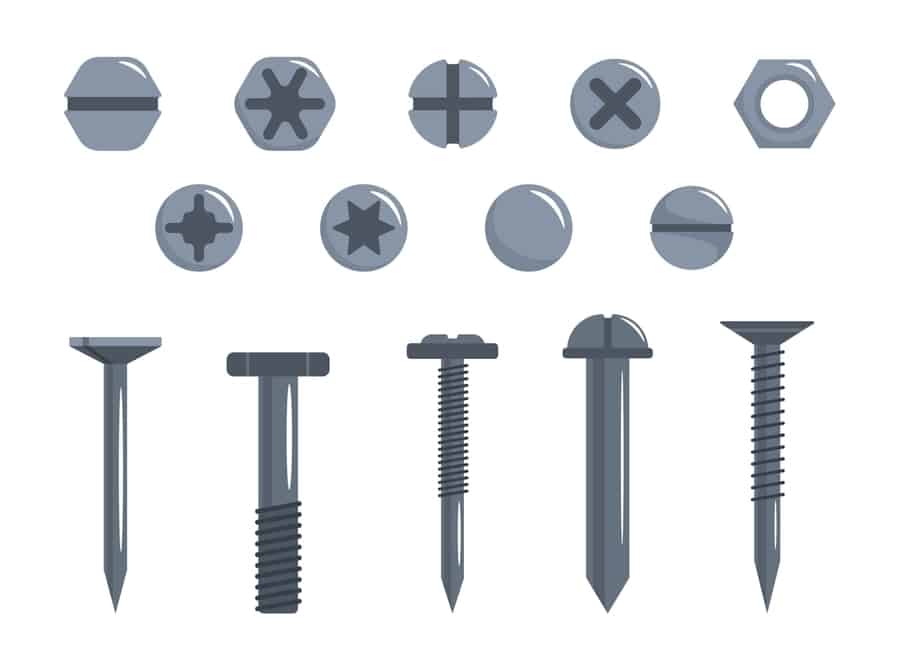

One of the first things that cause a screw to become stripped balls down to its design. The design of some screws can hold up more stress than others.

Some of the most common types of screws include the flat head, tri-wing head, binding head, external hex, etc.

The design of a screw impacts its ability to withstand getting stripped. If the point of contact between the screw and the screwdriver is too narrow, chances are high that it will get stripped.

When there isn’t enough contact between the screw and the screwdriver, it causes inefficient torque transformation and uneven force application causing it to become stripped.

2. Too Much Torque

Another reason screws become stripped can be because of excessive torque. When using a pneumatic or electric screwing tool, if the output torque is too much for the screw to bear, it will damage the screw.

It is important to note that every screw has a limited torque-bearing capacity. If you are unsure how much torque can damage a screw, using a mechanical torque wrench is best.

With mechanical torque, you can prevent excessive torque that can strip the screw, costing you more to get a replacement.

3. Wrong Size Screwdriver

The type of screwdriver you use also influences how well the screw holds up. Using the wrong size of a screwdriver to unfasten the screw can strip the screw.

For example, if the screwdriver is smaller than needed, it can expand the gap on the screw head, making it difficult to use the right-sized screwdriver to fasten or unfasten the screw.

So, if you want to protect the screw, ensure you double-check the screw head and get the right size. When the size is incorrect, torquing the screw to concentrate the force to a single point can cause further issues.

4. Rust and Corrosion

Also, it would help if you were cautious of rust and corrosion.

Screws are often made of metal susceptible to rust or corroding when the conditions are right. However, a lot of screws are treated to protect it from rusting. But if the screw is rusting, it is best to replace it.

When you try to unfasten a screw that is rusted, there is a high chance it will become stripped.

If screws made with copper are used, note that they can rust. In such cases, you should replace it with platinum or other pure metal like stainless steel that is highly rust resistant.

5. Poor Quality Screw

Finally, the quality of the screw also influences how well it holds up against stripping.

If the material used in making the screw is low-grade, striping under the slightest strain is common.

Even when you use a manual torque with a poor-quality screw, there is a likelihood it will become stripped.

Also, low-quality screws give out easily and tend to rust quickly.

How To Remove a Stripped Screw

If your screw is stripped, removing it can be challenging. Screwdrivers are useless when fastening a screw that has become stripped.

You can handle this situation in different ways, depending on the state of the screws.

Below are options to remove a screw when it becomes stripped:

I. Using a Plier

Pliers are the go-to tool to remove a stripped screw.

With pliers, you can clamp the screw as close to the base as possible and turn it counterclockwise.

II. Using a Knife

Another option you can use to remove a stripped screw is a knife.

This method works even when the screw head is missing.

With a knife, you can cut a bit of the area on the wood to have enough room to sink the plier.

III. Using a Hollow Extractor

You can use a hollow extractor to remove a stripped screw.

With this option, you must drill a hole into the word and around the stripped screw to complete the fear.

Conclusion

Conclusively, with this guide, hopefully, you don’t have any questions about stripped screws.

With these few tricks, you ought not to have issues with the screws in your project.

Always watch for the screw design, torque, screwdriver size, rust, corrosion, and poor-quality screws.

Frequently Asked Questions

Should You Replace a Screw Often?

In most cases, if the screw is high-grade, you don’t have to worry about replacing it often. But when the screws are made of high-grade material, they can stand the test of time.

Does Moisture Damage Screws?

Installing screws in a large environment makes them susceptible to high moisture content and other foreign elements that can cause rust. Ideally, you need to install screws treated against such moisture damage.